The Global Aluminum Die Casting market is anticipated to rise at a considerable rate during the forecast period, between 2023 and 2031. In 2024, the market is growing at a steady rate, and with the rising adoption of the strategies of key players, the market is expected to rise over the projected horizon.

The global Aluminum die-casting market was at 27.50 Billion in 2023 and is projected to achieve 39.61 Billion in 2030, at a Compound Annual Growth Rate (CAGR) of 5.35% during the forecast period. Rising use of aluminum in different end-use sectors, like transportation & telecommunication, is expected to boost market development during the forecast period. An increasing preference for high-strength & lightweight castings is a projecting pouring factor. In the transportation sector, companies must comply with rules to improve fuel efficiency & reduce harmful emissions, which is possible through the combination of lightweight supplies in the manufacturing of vehicles.

Production Segment Overview

Pressure die casting held a major revenue share of more than 77 percent in the year 2023. The big share is attributed to remarkable characteristics provided by the procedure with easy filling of the cavity & robust mechanical properties. The increasing inclination for pressure die casting is expected to push market development, particularly in the automotive segment during the forecast period.

Application Segment Overview

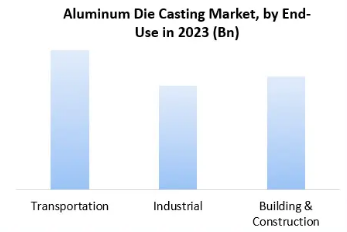

The transportation sector held a major revenue share of more than 63 percent in the year 2023. Within the transportation sector, lightweight vehicles are measured to be the major influence behind the development of aluminum products. The sector of die-cast measures is expected to rise by nearly 4.9 Kg by the end of 2023. The industrial sector held a significant revenue share in 2023. It comprises agricultural, construction, & mining devices. The aluminum cast products are used in the modules of the above-mentioned machinery. The increasing infrastructural expansions in Asian nations are anticipated to increase the demand for construction equipment through the forecast period. The produce demand in the B&C sector is dominated by the usage of aluminum die-cast products in houses, with numerous applications like door handles, roofing, & windows. The increasing replacement of iron & steel owing to the changing customer inclinations is impacting the market development on a positive note.

Regional Overview

APAC led the market and accounted for over 45 percent share of the worldwide revenue in the year 2023. The region is categorized by the occurrence of trained labor at low cost, which makes it the most profitable region for producers to set up production services. Moreover, a shift in the worldwide manufacturing landscape toward South Asian nations is anticipated to positively power the market development during the forecast period. China accounted for a major share of the regional market in the year 2023, seeing the widespread occurrence of end-use businesses in the nation. It is one of the major manufacturing centers in the world. Moreover, China spends a big amount on military & defense. Although China’s engineering actions were also impacted due to the COVID-19 epidemic, the nation reported a fast recovery compared to other shares of the world. North America is expected to witness steady development through the forecast period. The importance of reaching pre-Covid stages & the combination of sustainable keys is expected to enhance product demand in the area.

.png)

Growth Factors

► Aluminum die-casting is a method of producing aluminum products in desired shapes by pouring molten metal into a mound of the appropriate shape and size, yielding a finished product that meets the requirements. The output product of aluminum die casting is obtained by pouring metals under high pressure or injecting metal into the mound cavity. When extreme precision, complicated pieces, and precise details are required, the aluminum die-casting process is preferred.

► The qualities of aluminum such as resistance to corrosion are benefits that increase the feasibility of aluminum die-casting products for a variety of applications. The automobile industry is a major user of aluminum die-casting products, and the industry’s continued growth in manufacturing and sales may provide prospects for the aluminum die-casting market to expand.

► The aluminum die-casting market’s growth is being supported by increased demand for automobiles and consumer products. Furthermore, the military and defense sector’s growing investment in lightweight weapon systems is a major driver of market growth. In addition, rising usage in the building and construction, electronics, and mining industries has aided market expansion. However, price instability in the aluminum market and changing environmental requirements are expected to hinder market growth.

► As numerous reasons can cause the aluminum die-casting market to grow, some can limit it. One of the most significant disadvantages of aluminum die casting is the entrapment of gases in the aluminum due to permeability, which can cause product deformation and damage. Furthermore, the aluminum die-casting method is not ideal for the design of large parts, making it unsuitable for large parts and diverting clients with such needs away from the aluminum die-casting industry.

► The rising usage of aluminum, die casting for various purposes, and acceptance of high strength and lightweight castings, notably in the auto sector, are among the primary drivers driving the aluminum die casting market expansion. Furthermore, growth in the substitution of aluminum for iron and steel in the automotive and automobile sectors, as well as increased funding in these sectors, would create lucrative opportunities for the growth of the aluminum die-casting market during the forecast period.

► However, the increasing substitution of aluminum alloys with magnesium, as well as the economic crisis in developed countries, is among the key factors restraining the growth of the aluminum die-casting market during the forecast period. The global aluminum die-casting market has been supported by growing demand for aluminum casts in the electronics sector, as well as greater penetration of die-casting parts in the automobile and automotive industries.

► Moreover, the automotive and automobile industry’s need for lightweight has been fueled by the swift implementation of stringent government regulations aimed at lowering emissions and improving fuel efficiency. As casting technology advancements, highly accurate machines and gadgets are increasingly used to improve the quality and durability of aluminum casts for a variety of applications.

<< Previous: APPLYING FSW TECHNOLOGY AT KRICO Next: Part 2_Vietnam Aluminum Die Casting Market >>

Việt Nam

Việt Nam